Rapid tests to screen food crops for destructive viral infections

New point-of-care virus diagnostic kits, which will work similarly to a home pregnancy test or a Covid-19 rapid test, could soon help tomato, potato and banana farmers in South Africa detect outbreaks before they cause major losses.

CSIR researchers are developing the antibody-based biotechnology behind the rapid tests in partnership with the Agricultural Research Council (ARC), starting with tomato spotted wilt virus, pepper ringspot virus and banana bunchy top virus, respectively.

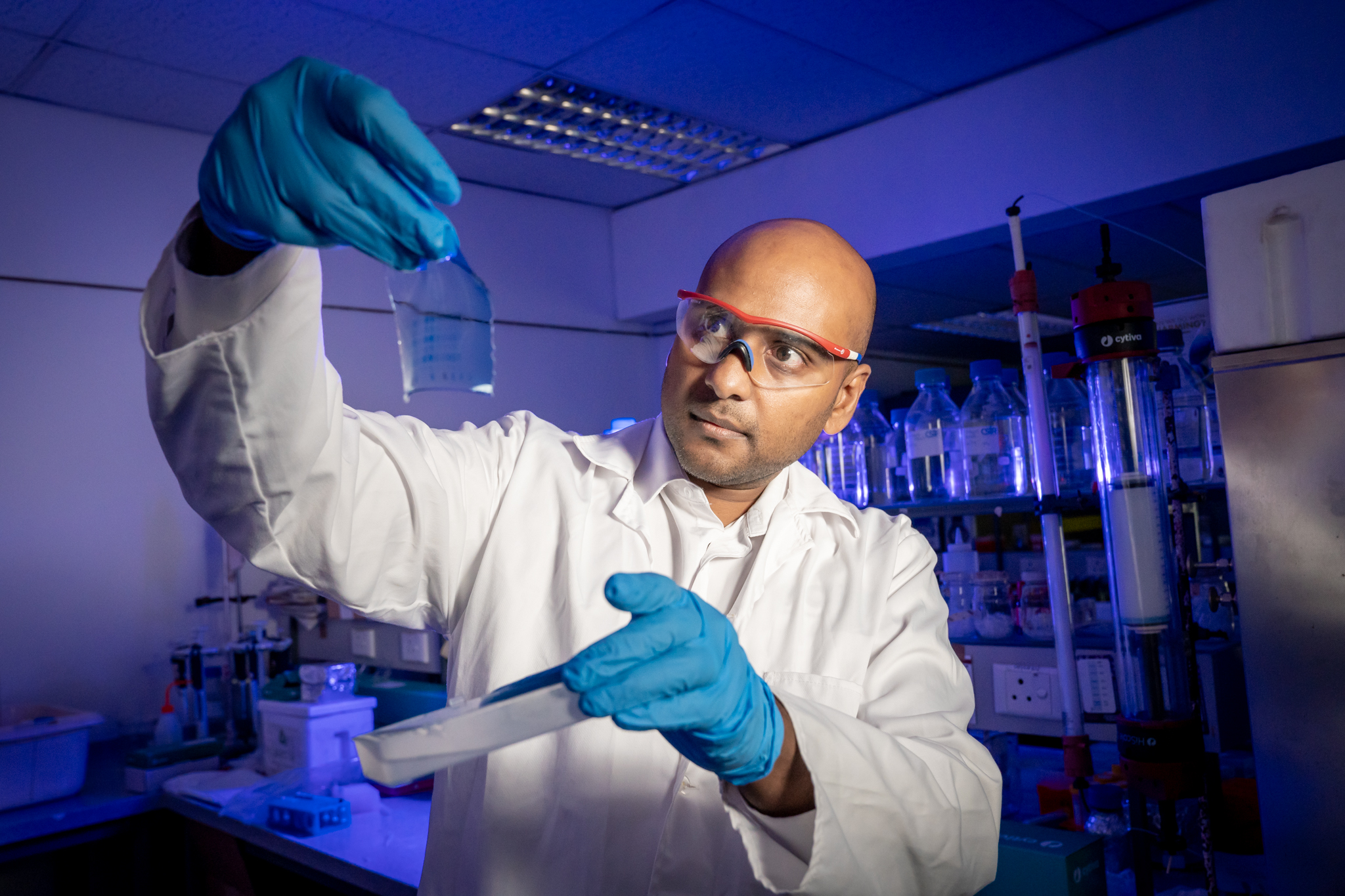

“We want the technologies and the products we are working on to add value in a laboratory setting, as well as in the field in southern Africa,” says biotechnologist Dr Priyen Pillay, a lead CSIR researcher working on the project.

He explains that while similar test kits can be imported from international suppliers, some do not detect local or indigenous viral strains.

“I have had a look at the genetic sequences of the proteins that these international antibody kits bind to and they are often significantly different from those that are devastating our local crops,” he says. “So, it makes sense that those kits are not working for our farmers and we realised that we would need to find our own solution.”

Pillay says the CSIR is using bacteria and plants to amplify target proteins unique to these local strains, which will then be used to create matching antibodies for use in diagnostics.

“We have managed to express the viral proteins in E. coli bacteria and the data is looking very good,” he says. “We are now upscaling for mass spectrometry analysis to confirm the identity of each protein and will then try to express the same viral proteins in tobacco plants.”

Fellow CSIR biotechnologist Dr Lusisizwe Kwezi says the novelty of this approach compared to conventional methods, is that it is completely animal free, making it both less costly and less cruel.

“Using E. coli bacteria and tobacco plants to express viral proteins has been proven to be much cheaper than conventional bioprocesses or production systems that involve animals, mammalian cells, insect cells and other eukaryotic-based technologies,” he says.

Pillay and Kwezi explain that the ARC currently relies on lengthy and expensive laboratory testing using finite stocks of antibody serums that were generated in goats.

“Our collaboration thus arose from the need for a sustainable, more environmentally friendly antibody production platform,” says Pillay.

He explains that the viral proteins they have expressed in bacteria and tobacco will now go to the CSIR’s proteomics team to find matching antibodies. “They will look for antibodies that bind most strongly to the viral proteins within the anti-serum provided by the ARC and then they will determine the genetic sequence of the antibodies.”

With the antibody sequence precisely matched to local strains, Pillay and Kwezi can again use tobacco plants to generate large amounts of pure, high-quality antibody.

“The tobacco plant has the molecular machinery to produce complex proteins like antibodies,” says Pillay. “We inject the antibody sequence into the plant using an agrobacterium vector and within seven days we can purify the antibodies.”

He says they plan to hand over pure, highly specific antibodies to the CSIR’s diagnostics team, led by Dr Amanda Skepu. These antibodies will be immobilised onto special paper strips, which will then be assembled and packaged into lateral flow test devices using advanced instrumentation. The resulting devices will be provided to the ARC for testing before the end of 2026.

As the entire protein discovery process, antibody production and immobilisation and lateral flow device assembly can be done in-house at the CSIR, the project will serve as a proof-of-concept that plant-based antibody production can be used for any medical or agricultural application, including rapid tests.

Plans are also in place for the successful crop virus rapid test kits to be commercialised and manufactured at scale locally.

“This project therefore speaks to security of supply and self-sustainability for South Africa’s agricultural sector, but also to cost-effective manufacturing,” says Kwezi.

He says both skilled and unskilled farm workers, at large agribusinesses or on smallholdings, as well as agricultural extension officers and port officials, will be able to use the simple test-strip device in the field to diagnose or survey viral infections in crops and produce. Lateral flow devices yield results in as little as 10 minutes, thereby addressing long delays and transport costs associated with laboratory testing.

“When I look at the expertise of the ARC and the CSIR, and how they complement each other to solve a problem of national importance within the agricultural sector; for me, that's phenomenal,” says Dr Duduetsang Saku, a business development manager at the CSIR. “A project like this reflects our competencies as a nation and a capable state and it shows that collaboration is important.”

She says these first three antibody-based rapid tests will help safeguard tomato, potato and banana crop yields. They will also help ensure that the produce meets export standards and fetches fair prices in global markets.

The technology is co-funded by the CSIR and the ARC It addresses SDG 2.

Contact Person

Dr Priyen Pillay

Dr Lusisizwe Kwezi

Dr Duduetsang Saku

ppillay3@csir.co.zalkwezi@csir.co.zadsaku@csir.co.za